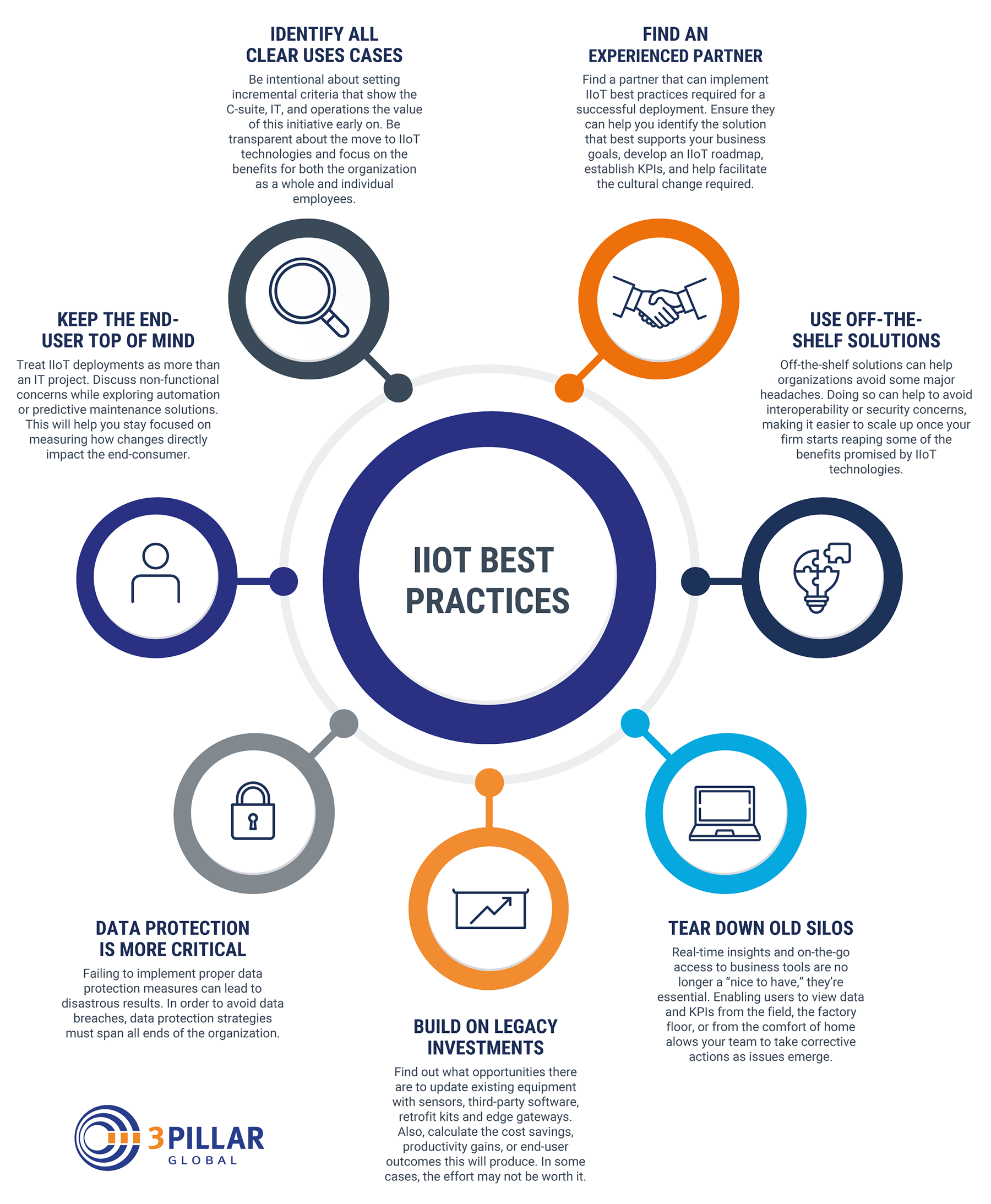

IIoT Standards & Best Practices

Between new revenue streams and never-before-seen insights, the Industrial Internet of Things (IIoT) promises a massive set of benefits that, done right, could set the stage for lasting success.

There’s business value to be gleaned from every connected sensor, device, and piece of machinery via big data analytics, automation, and real-time computing. And, as a result, organizations are eager to tap these benefits for themselves.

Whether the motivation comes from the desire to monitor environmental conditions, improve safety, or finally put those mountains of siloed data into action, there is some internet of things best practices organizations should know.

While IIoT remains something of a wild west as far as standards and procedures are concerned, the Industrial Internet Consortium (IIC) recently released a white paper that details IIoT best practices gleaned from pilot programs across several sectors and business cases. The report, entitled, A Compilation of Testbed Results: Toward Best Practices for Developing and Deploying IIoT Solutions revealed that despite varying objectives, some common IIoT practices emerged.

Identify Clear Use Cases (and Make Them Known)

Realizing the ROI of IIoT is something that takes place over the course of several years, as opposed to a matter of weeks such as measuring the performance of an ad campaign or the success of a webinar. As such, organizations need to be intentional about setting incremental criteria that show the C-suite, IT, and operations the value of this initiative early on.

The IIC report recommends that organizations plan for the long-term, using short-term objectives to mark the path toward progress. For example, one testbed team began by localizing the tools and assets used for internal processes. Later, the goal post shifted–this time to include tools used in the logistics process such as forklifts.

Following these recommendations will help you achieve buy-in from the top, and at the ground level, motivating employees, and helping leaders understand what success looks like and how to measure progress. It’s also worth noting that many of the characteristics that make IIoT technologies such an asset for organizations, on the whole, can open up all sorts of “people problems.”

It’s also important to be transparent about the “why,” “what,” and “how” behind the move to IIoT technologies, focusing on the benefits for both the organization as a whole and individual employees.

Another testbed team found that though their initial conversations were purely technical, over time, talk started to shift toward how new solutions brought value to the organization. The team began looking toward what was next (aka continuous improvement), discussing new use cases and their benefits–something that improved adoption across the entire organization.

Keep the End-User Top of Mind

A report from the Inmarsat Research Programme revealed a strong correlation between the strength of an organization’s data strategy and its understanding of the consumer.

IIoT deployments generate massive amounts of data, and decisions need to be made about how and where that data is stored. As such, the report notes that developing strategies around analysis, security, and information sharing are essential for ensuring that organizations achieve their target outcomes.

The IIC report echoes the sentiment and advises companies to treat IIoT deployments as more than an IT project. Teams found success when they discussed so-called “non-functional concerns” while exploring automation or predictive maintenance solutions, which helped them stay focused on measuring how changes directly impacted the end-consumer.

In the context of an experimental project like the IIC testbeds, organizations might start building out a framework for collecting data based on your business goals, starting with a series of questions:

- What constraints will the proposed solution need to operate under?

- What resources are available to implement the solution?

- Which metrics represent success?

- What milestones/objectives are you measuring?

Data Protection Best Practices for IIoT

Failing to implement proper data protection measures, as well as a process for detecting threats, and reporting data breaches can lead to some disastrous results, including:

- Costly service disruptions

- Regulatory fines

- Reputational damage

- Stolen IP

- Injury or death

In another white paper from the IIC, Data Protection Best Practices, data protection strategies must span all ends of the organization.

This includes data security, integrity, and privacy across all categories–operational data, employee and customer data, audit logs, IP, system and configuration data, and anything else your connected system might generate.

Build on Legacy Investments

Many manufacturing facilities already have solutions in place that automate at least some daily operations. And while many of these solutions aim to provide added controls and visibility, businesses are leaving opportunities on the table because not everything is connected yet.

In these cases, it’s not so much an issue of scrapping your old tech and replacing it with something new. After all, the average lifespan for most manufacturing equipment is between 30-40-years— a far cry from the two-year standard of today’s laptops and smartphones. Sensors, third-party software, and tools like retrofit kits and edge gateways can help here.

For example, pre-IoT equipment can be retrofitted using kits that almost function like an adapter, allowing them to collect data on things like temperature, pressure, vibrations, and more. According to Hewlett Packard, edge gateway devices have been particularly effective in bridging the gap between IT and operations— particularly if an organization has a lot of pre-internet assets.

That said, don’t forget to follow this internet of things best practice: before buying kits and new software, calculate the cost savings, productivity gains, or end-user outcomes that retrofitted assets will likely produce. In some cases, the effort may not be worth it.

Tear Down Old Silos & Avoid Building New Ones

Another internet of things best practice is developing a system for leveraging your existing software investments in a way that allows you to unify data that currently resides in multiple silos. The idea is to give your team the tools they need to make data-driven decisions on-the-fly.

Real-time insights and on-the-go access to business tools are no longer “nice-to-have,” they’re essential IIoT best practices. Enabling users to view data and KPIs from the field, the factory floor, or from the comfort of home allows your team to take corrective actions as issues emerge.

While most organizations deal with some data silos, you’ll want to be careful to avoid making those barriers even worse.

Make sure you standardize the processing, organization, and storage of all data collected. The goal is to create a living record of all business activities that any employee — current or future — can access and get a clear picture of the organization’s health.

Finally, implementing a local processing solution, before sending data to a centralized cloud storage system can help ensure data is clean and easy to analyze.

In this case, the challenge lies in identifying the integration points where siloed data can be released, processed, and analyzed across departments, locations, and roles. Part of this, too, is developing a reporting process that includes tailored reports based on each person’s relationship to the insights collected.

Use Off-the-Shelf Solutions Where Possible

There’s long been a debate among business leaders as to whether it’s better to build IIoT solutions or buy.

On the one hand, it makes sense that you might look toward a custom solution. Every business has a unique set of requirements, so it only makes sense that you might assume that a custom build is the only way to guarantee that your smart factory, fleet, or farm is designed to your specifications.

It’s a logical argument, to be sure, however, given the complexities of IIoT solutions, along with the potential fallout of a compromised system, off-the-shelf solutions help organizations avoid some major headaches.

According to the report, off-the-shelf solutions offer some recognized standards, which will become important as your IIoT system matures. Organizations can avoid interoperability or security concerns, making it easier to scale up once your firm starts reaping some of the benefits promised by IIoT technologies.

Find a Partner Well-Versed in Internet of Things Best Practices

In the Inmarsat report mentioned above, researchers noted that a lack of in-house skills was the top barrier to a successful IIoT deployment. More so than cyber threats and the high cost of adoption.

[adinserter name=”IIoT Closing”]

Recent blog posts

Stay in Touch

Keep your competitive edge – subscribe to our newsletter for updates on emerging software engineering, data and AI, and cloud technology trends.